Fahadiovana avo lenta 99.95% Wire Tungstène

Karazana sy Habe

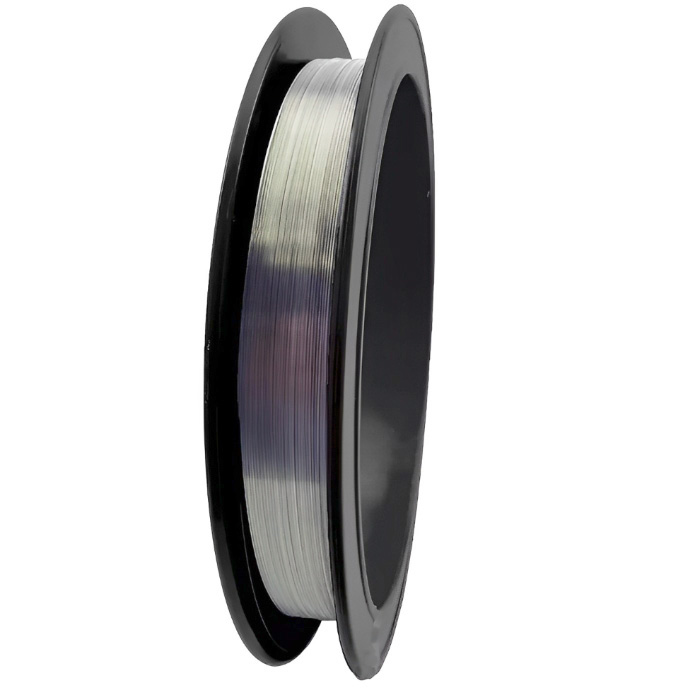

Ny tariby W dia mainty mahazatra rakotra graphite.Rehefa nesorina ny graphite dia famirapiratana metaly izany.

| fanendrena | Tungstène Content | Votoatin'ny singa tsy madio | |

| sokajy | tsirairay | ||

| WAL1, WAL2 | ≥99,95% | ≤0,05% | ≤0,01% |

| W1 | ≥99,95% | ≤0,05% | ≤0,01% |

| W2 | ≥99,92% | ≤0,08% | ≤0,01% |

| Fanamarihana: Tsy tafiditra ao anatin'ny loto ny potasioma. | |||

Fandeferana savaivony (%):

| Savaivony (μm) | Lanja (mg/200mm) | Lanja(mg/200mm) Fandeferana(%) | Fandeferana savaivony(%) | ||||

| Grade 0 | Grade 1 | Grade 2 | Grade 0 | Grade 1 | Grade 2 | ||

| 5≤d≤12 | 0.075~0.44 | - | ±4 | ±5 | - | - | - |

| 12 | >0.44~0.98 | - | ±3 | ±4 | - | - | - |

| 18 | >0.98~4.85 | ±2 | ±2.5 | ±3 | - | - | - |

| 40 | >4.85~19.39 | ±1.5 | ±2.0 | ±2.5 | - | - | - |

| 80 | >19.39~272.71 | ±1.0 | ±1.5 | ±2.0 | - | - | - |

| 300 | >272.71~371.79 | - | ±1.0 | ±1.5 | - | - | - |

| 350 | - | - | ±1.5 | ±2.0 | ±2.5 | ||

| 500 | - | - | ±1.0 | ±1.5 | ±2.0 | ||

Dingana ara-teknika:

Tungstène Powder → Isostatic Pressing → Bar Billet → Sintering → Semi-vita bar → Forging → Swaging → Drawbench → vokatra farany → Inspection → Fonosana

Toetoetra

1. Avo levona sy avo harafesina fanoherana

2. Super thermal fahombiazana

3. 99.95% Fahadiovana

4. Fisehoana: volafotsy fotsy / volondavenona metaly famirapiratry ny elektrôlytika voaporitra tungstène tariby dia tokony ho malama, madio, volondavenona volafotsy amin'ny metaly luster.Ny tariby tungstène dia manana endrika endrika tsara, fiainana fohy ary fahombiazana amin'ny jiro hariva.

Applications

1. Famokarana ampahany loharanon-jiro elektrika sy singa vaccum elektrika;

2. Mamokatra singa fanafanana sy refractory faritra amin'ny mari-pana ambony lafaoro;

3. Mamokatra singa fanafanana ampiasaina amin'ny vaccum metalizing na plating.